What is urethane casting?

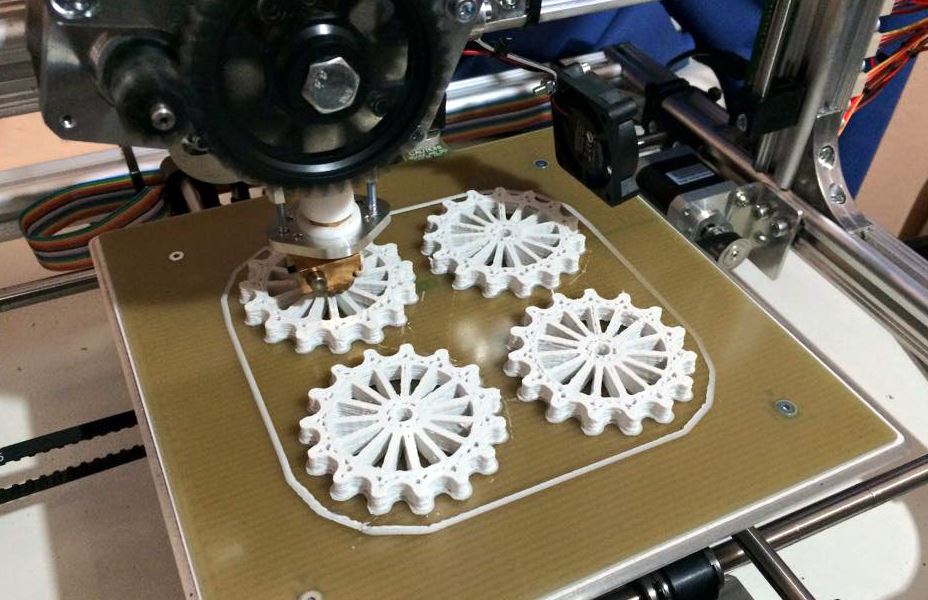

We are often asked by customers what is urethane casting and what is the process of urethane casting? Let us first understand literally what urethane casting is? From a literal point of view, “replication” means copying. A mould is a mould of a mould. Understood, it means copying a product from a mould. What is the process of urethane casting? What does he have to do with 3D printing? First, it is necessary to use 3D printing to make a prototype, which is a master mould, then copy a set of moulds through the process of urethane casting, and finally copy the product through this mould. The process is as follows:

Then the urethane casting process has existed in the prototype industry for so many years, why has it always existed and is related to 3D printing? I want to share with you both the advantages and disadvantages.

What are the advantages of urethane casting?

Urethane casting usually means that your product is slightly larger, such as 60mm×60mm×60mm or 100mm×100mm×100mm or larger. If you use 3D printing directly, for example, you will make 50 pieces. Even in the case of 100 pieces, the cost may be more expensive, so if urethane casting is used, the cost may be slightly cheaper and more economical.

First of all, the problem to be solved by urethane casting is that if there is no prototype, that is, the master mould in the picture above, the urethane casting process cannot be completed. Because urethane casting is to copy a product, it must solve a source part. The problem is that the source piece is in our prototype industry, and it is usually called a prototype piece. This prototype was usually made by CNC machining in the past, but now because of the rapid development of 3D printing, urethane casting often uses 3D printing to make a prototype, and then the urethane casting is solved after the processing is completed. Problems with prototypes.

What materials can be compounded by urethane casting? Please pay special attention to the following paragraph. The materials that can be compounded by urethane casting are as follows, similar to ABS, similar to POM, similar to PP, similar to PA, similar to PMMA and soft rubber. These materials are very commonly used, so why I would like to remind everyone to listen to the following sentence, which is similar to two words, it can reproduce ABS, POM, PP, PE, PMMA are all similar, it It is different from the materials that we use plastic molds to produce. It is only the materials of these physical properties that are close to each other. Of course, there is no similar problem with soft glue.

What are the disadvantages of urethane casting?

The model prototypes produced by urethane casting can be adjusted in various colours. For example, I want urethane casting an ABS red, yellow, and green, can I? Can. However, the red, green, and yellow produced by urethane casting are different from the colours on our international letter. If you have high colour requirements, even red, yellow or green urethane casting must be sprayed up by hand later, because the colour of urethane casting is far from the international standard. In terms of soft rubber, it can be urethane casting 10 degrees 15 degrees 20 degrees, directly to 90 degrees, you can choose this softness and hardness problem.

Another disadvantage of urethane casting is that we judge based on experience. If your product is within 100mm, the tolerance of urethane casting is usually about plus or minus 0.2mm, but if your product is relatively large, for example, If it is greater than 100mm, such as 200M or 300mm, then the tolerance may go to plus or minus 0.5mm. Because urethane casting depends on the level of the urethane casting master, it may shrink and deform. Moreover, a set of urethane casting moulds is usually not recommended to exceed more than ten pieces, because the more urethane casting to the back, the greater its shrinkage and deformation.

The third disadvantage is that urethane casting has a longer delivery time because of the process of pouring out the prototype mould from the mould in its process.

Finally, I will use one sentence to summarize. If your product prints a large number of pieces each time and does not require precision, you can consider using this urethane casting method, but if your number of pieces is the same product every time In the case of a small number of pieces, and relatively small! And if there is a requirement for accuracy, then I do not recommend that you use urethane casting to do it. I still recommend that you use 3D printing.