With the rapid development of China’s manufacturing industry, the sheet metal processing industry has also developed and expanded. Now sheet metal involves various fields, such as environmental protection, medicine, engineering, IT, etc., but for any sheet metal product, it has A certain technological process, the selection of sheet metal processing process and materials depends on the quality and service life of sheet metal products, so how to select materials for products has become the top priority

Material selection

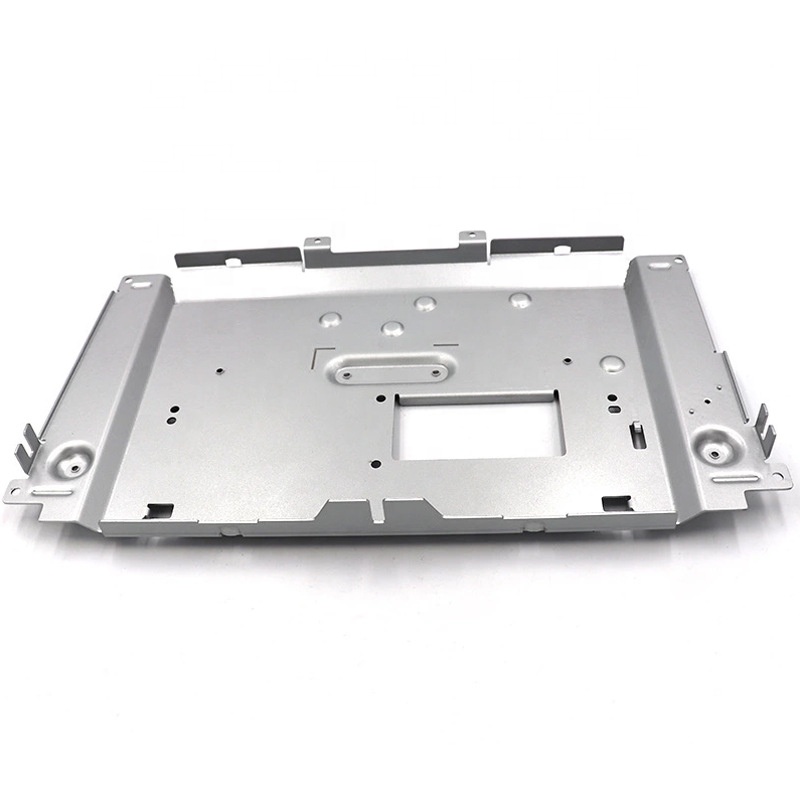

The materials generally used in sheet metal processing include cold-rolled sheets, hot-rolled sheets, galvanized sheets, aluminum sheets, aluminum profiles, stainless steel sheets, etc. According to the different functions of the product, the materials used are different, and generally need to be considered from the product and its use and cost. , you can refer to the following instructions:

Cold-rolled sheet: mainly used for electroplating and baking paint parts, low cost, easy to form, material thickness of 0.2-4mm;

Hot-rolled sheet: material T≥3.0mm, also used for electroplating, paint parts, low cost, but difficult to form, mainly flat parts;

Galvanized sheet: mainly used in automobile manufacturing, refrigerators, construction, ventilation and heating facilities, and furniture manufacturing;

Aluminum plate: generally used for surface chromate, oxidation, silver plating, nickel plating, high cost, suitable for household appliances and electronic product casings;

Aluminum profile: a material with complex cross-sectional structure, which is widely used in various boxes, and the surface treatment is the same as that of aluminum plate;

Stainless Steel: Mainly used for any surface treatment, high cost. Mainly used in daily life, food industry, pharmaceutical and so on.

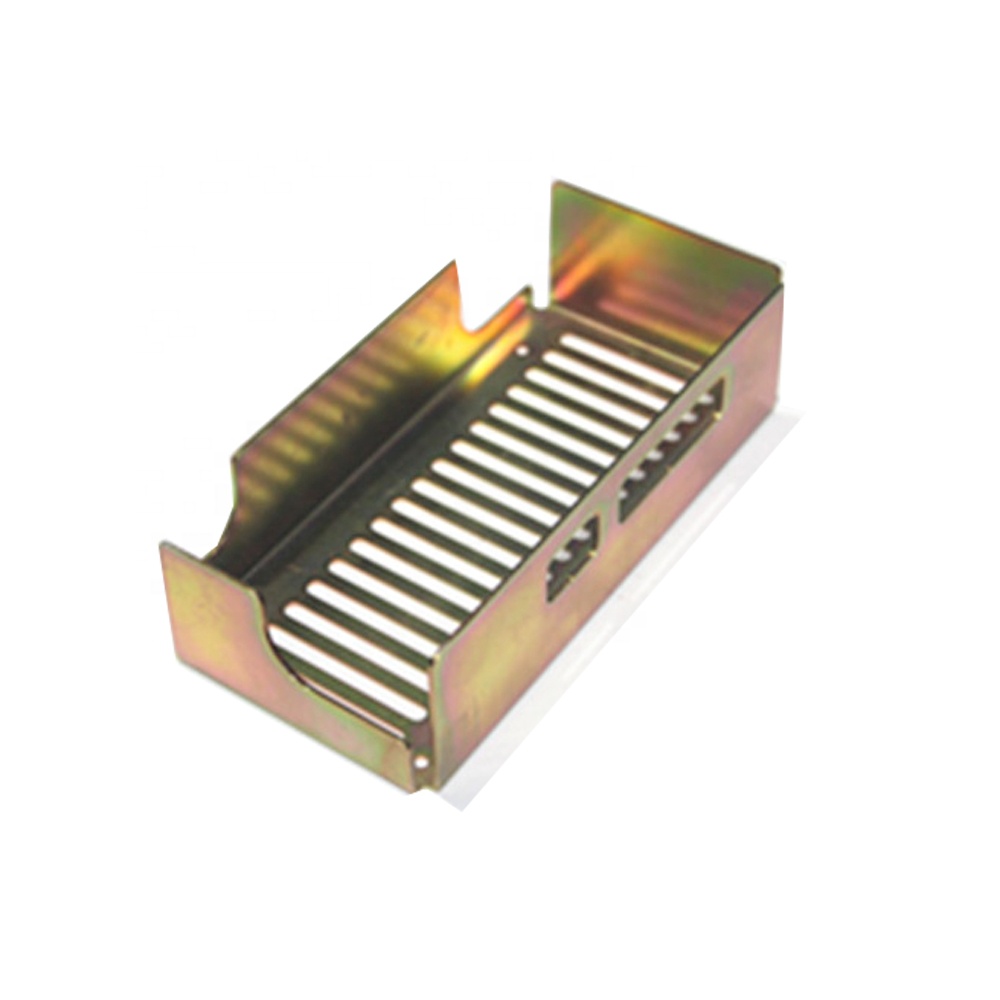

Sheet metal processing

01 Blanking

There are mainly the following methods for unloading:

Shearing machine: Use the shearing machine to cut out the shape of the unfolded drawing. If there are punching and cutting corners in the length and width dimensions, then turn the punching machine to combine with the die for punching and cutting corners to form;

Punching machine: It is to use a punching machine to punch the flat parts after unfolding the parts into various shapes on the plate in one or more steps.

NC CNC blanking: When NC blanking, the CNC machining program must first be written. Using programming software, the drawn unfolding diagram is written into a program that can be recognized by the machine tool processed by NC data, so that it can be punched out on the flat plate step by step according to these programs. Flat parts of various structural shapes;

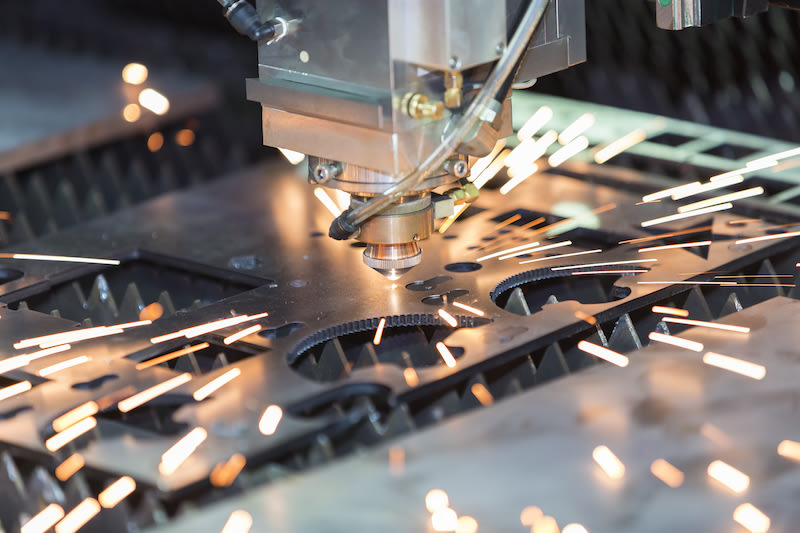

Laser cutting: Using the laser cutting method, the structure and shape of the flat plate are cut out on the large plate, and the program needs to be programmed like NC cutting. It can cut flat parts of various complex shapes, with high cost and accuracy greater than 0.1mm;

Sawing machine: mainly used for aluminum profiles, square tubes, round tubes, round bars, etc., with low cost and low precision;

Plasma cutting: mainly for non-ferrous metals (stainless steel, aluminum, copper, titanium, nickel), the cutting effect is better.

02 Flanging

Also called hole drawing, it is to draw a slightly larger hole on a smaller base hole, and then tap it. It is mainly used for thin plate thickness and normal shallow flanging around the hole, and the thickness basically does not change. Then you can tap directly.

03 Punch

It is a processing process that uses mold forming. Generally, punching machines include punching, corner cutting, blanking, punching convex hulls, punching and tearing, punching, forming and other processing methods. The processing requires corresponding molds to complete operations, such as punching. Hole blanking dies, convex hull dies, tearing dies, punching dies, forming dies, etc.

04Press riveting

Pressure riveting mainly includes pressure riveting nut, screw, loose, etc., which is completed by hydraulic riveting machine or punching machine, riveted to sheet metal parts, and expansion riveting method, which needs to be paid attention to the directionality.

05 Bending

It is a part that folds the flat part into the required radian or camber. Its processing needs to be completed by a bending machine and a corresponding bending die. It also has a certain bending sequence. The principle is that the first folding that does not interfere with the next knife will cause interference.

06 Welding

Welding, also known as welding, is a manufacturing process and technique for joining metals or other thermoplastic materials by heat, high temperature, or high pressure.

Classification:

Fusion welding: argon arc welding, submerged arc welding, electroslag welding, gas welding;

Pressure welding: heating and pressing, cold pressing;

Brazing: electrochromic welding, copper wire.

Welding method:

CO gas shielded welding;

argon arc welding;

spot welding, etc.;

Robot welding.

07 Surface treatment

Surface treatment generally includes phosphating film, electroplating colorful zinc, chromate, baking paint, oxidation, etc. Phosphating film is generally used for cold-rolled sheets and electrolytic sheets; electroplating multicolored zinc is generally used for surface treatment of cold-rolled sheets; chromate and oxidation are generally used for surface treatment of aluminum sheets and aluminum profiles; the specific surface treatment method is based on customers. depending on the requirements.

08 Assembly

Assembly is to assemble multiple accessories or electronic components together according to the assembly process to make it a complete product. During the assembly process, attention should be paid to the protection of materials and parts, and must not be scratched to ensure that the product is intact.

Quality control of sheet metal products

To understand the needs of customers, to have a comprehensive understanding of the customer’s products when there is a new product or a new order, as well as to understand the customer’s requirements for the appearance, size of the product, and the use of the product, which needs to be signed and confirmed by both parties;

According to the customer’s requirements for the product, plan different product processes, and at the same time explain the precautions on the process drawings;

The craft department gets the drawings to make the craft drawings (expanded drawings). The drawings drawn by the craftsman must be checked by another craftsman, and passed the review of the craft project. After the review, it will be sent to the workshop after being signed and confirmed by the person in charge;

The first piece of CNC blanking must undergo full inspection, including size, appearance, etc. In mass production, all the first pieces must pass the inspection before mass production;

When bending, confirm the bending direction and bending size of the first piece, and start mass production after confirmation, and re-inspection is required to replace the operator or replace the mold;

When riveting, consider the height of the stud and select different molds, and then adjust the pressure of the press to ensure that the stud and the surface of the workpiece are flush, and then perform batch bending after confirmation to avoid scrapping the workpiece;

For the finished welding or bending products, the size should be sampled according to the drawing requirements. During the sample inspection, each size should be confirmed. At the same time, the appearance should be fully inspected. The unqualified accessories should be adjusted in time, and the inspection report should be filled out at the same time;

The appearance of surface-treated products should be fully inspected to ensure that there are no scratches on the surface. Surface treatment is an important guarantee for extending the service life of the product;

Products that fail to pass the inspection must not be shipped, and should be repaired. Serious problems need to be reprocessed.